Texas, international robotics organizations, lightbulbs and machining.

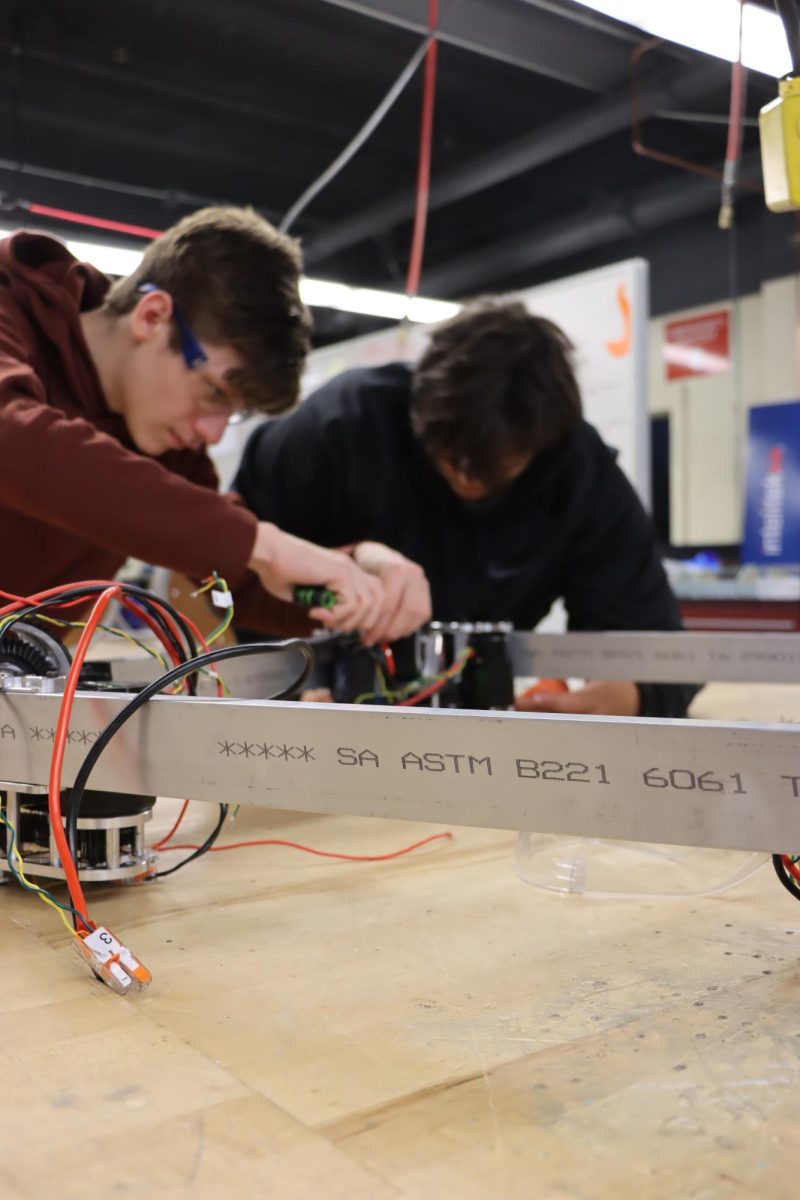

These are the unlikely topics of conversation in room 108, after the final school bell has rung, while Robotics Club, also dubbed the Horns of Havoc, is meeting. There are layers to every club, sport, and class, so of course Robotics is no different. From the sci-fi aspects of competitions to cutting their own metal parts, second-year mentor and STEM teacher Robert Kroker sums the club up best as “the hardest fun you’ll ever have.”

Though students join Robotics for numerous reasons, most know little about the nature of Robotics itself. Whether they enjoy programming, cutting custom parts, or planning the precise inner workings of a robot, all members develop skills they didn’t think they would.

“Normally, I see more improvement in the students in the club than I do in my own classes,” Kroker said. “They have a bigger motivation to do the work, to learn the stuff. It’s really cool to be part of something that’s bigger than yourself.”

As a mentor, Kroker shows the students the lesser-known aspects of machining, handles paperwork, and occasionally helps with building.

“My biggest goal in life is to collect light bulbs, when people have that aha moment, that sudden realization,” Kroker said.

And seeing as the program has been to the World Competition twice in the past, light bulbs haven’t been hard to collect. Senior Colin Nelson is captain of the team, and throughout his time with the team, a number of those lightbulbs have blinked to life over his own head.

“I came in as a programmer, so I was expecting to be programming the whole time, but I ended up doing all these random things,” Nelson said. “I really enjoy machining, because it’s not something I ever thought I would do, since I’ve never taken a class on it or anything, but it’s a fun skill to learn.”

The season begins with an announcement of which challenges the robots will be expected to perform in competition.

“The challenge that we have this year involves picking up PVC pipes. They’re a foot long, four and a half inches in diameter. We have to pick them up and put them on these poles that are sticking up. There’s four different levels, from a couple feet to I think six and a half feet in the air,” Nelson said. “We also have dodge balls, 16 inches in diameter, that we can put in a hole in a wall, or shoot into a net that’s eight feet up.”

After some strategic analysis, the team decided the best strategy would be to focus on the PVC pipes.

“Our primary season goal was to finish faster than last year, because last year we were working on our robot all the way up until our first competition,” Nelson said. “We wanted more time to practice with it and make sure that everything was working well.”

Once their robot is finished, they’ll be off to Snohomish and Bonney Lake to compete and possibly make their way to Cheney, where they can qualify for the World Championship in Dallas, Texas.

“Anyone in Washington, Oregon [and] Idaho can compete, and there’s events scattered all over those states,” Nelson said.

The competition itself is reminiscent of a blend between Star Wars, Hunger Games and the Maze Runner.

“There’s six robots on the field, which is like a tennis court-sized area. Three robots per team, [or] alliance is what they call it, and then they try to score as many points as possible, and whoever gets the most wins,” Nelson said.

Rankings are determined by a points system. Match wins, and specific accomplishments during the matches, are combined to determine the final standings.

“There’re usually 30 teams at a competition, and from that the top eight are picked to be Alliance captains. They pick other teams to join their alliances, there’s a double elimination bracket, and a group of three teams is crowned the champions of that event,” Nelson said.

Without most students being aware of it, this world of futurism and science fiction is running in time with the rest of the Puyallup School District. The only school without a team is Rogers.

“It’s not something I even knew existed until I saw it,” Nelson said. “These competitions happen every year, and there’s so many of them around, but I never even knew about them until I started. I thought it would just be [putting] something together and going to a couple local schools to compete, but it’s really a lot bigger than that.”

The problem-solving facet, as well as the interconnected community, are sophomore Matthew Barker’s favorite aspects of the club.

“I feel like my experience as a first-year member is different because right now, I’m getting taught and instructed on what to do,” Barker said. “I learn how to work on the machines, and how to do the manufacturing and building itself.”

Even the smallest problem with manufacturing can sometimes lead to major consequences.

“I feel like something that we do that surprises other people is the amount of planning and problem-solving that we have to do. If there’s one small issue, sometimes we have to redesign the entire thing,” Barker said. “It can just be as small as swapping one piece.”

But despite the roadblocks, the team sticks together through thick and thin.

“Especially right now, as we’re in build season, it’s a lot of a team effort. Some stuff are you’re sent off to do individually, but if you need help, it’s perfectly fine to ask,” Barker said. “It’s a lot more of a team effort than an individual.”